Top Wholesale Asphalt Cutters - Quality Products from Leading Suppliers

If you need high-quality asphalt cutters, Ningbo Max Machinery Co., Ltd. is your dependable supplier for wholesale construction products. Our asphalt cutters are engineered for durability and efficiency, allowing you to handle any task with confidence. Featuring advanced attributes and sturdy construction, our cutters ensure clean and precise cuts, helping you save time and resources. We cater to the unique requirements of B2B buyers by delivering products that meet industry standards at competitive prices. Whether you’re a contractor aiming to enhance your equipment or a distributor seeking to broaden your product range, we're committed to supporting your business's growth. Choose our asphalt cutters for the quality and performance that can elevate your projects. Let’s connect to discuss how we can assist you.In-Depth Analysis of Methods Asphalt Cutter From Concept to Delivery Where Service Meets Innovation

At MAX MACHINE, we understand that the world of asphalt cutting is rapidly evolving, driven by both innovative technologies and the pressing needs of global infrastructure development. Our journey from concept to delivery of asphalt cutters is a testament to our commitment to blending youthful energy with industrial expertise. We prioritize a client-first ethos, ensuring that each product not only meets but exceeds the stringent requirements of our clients, making their projects more efficient and effective. Our in-depth analysis of asphalt cutting methods reveals a spectrum of approaches that address varying challenges across diverse terrains and project scales. From state-of-the-art cutting technologies that enhance precision and speed to sustainable practices that minimize environmental impact, our solutions are designed with the future in mind. We believe that innovation lies at the heart of effective service delivery. By leveraging our dynamic team’s fresh perspectives alongside seasoned industry insights, we are adept at creating tailored solutions that cater to the unique demands of global purchasers. At MAX MACHINE, we are passionate about forging strong partnerships with our clients. This not only involves providing advanced asphalt cutters but also offering comprehensive support throughout the entire process—from selecting the right equipment to after-sales service. We pride ourselves on being a one-stop solution provider, ensuring that our clients receive not just products, but also the expertise necessary for success in their engineering challenges. In the ever-competitive landscape of global procurement, MAX MACHINE is your key partner in innovation and reliability.

In-Depth Analysis of Methods Asphalt Cutter From Concept to Delivery Where Service Meets Innovation

| Method | Description | Material Compatibility | Advantages | Limitations |

|---|---|---|---|---|

| Rotary Cutter | Utilizes a rotating blade for precise cutting. | Asphalt, Concrete | High precision and clean cuts. | Requires high maintenance; slower on thick materials. |

| Hydraulic Cutter | Employs hydraulic power for optimal cutting force. | Asphalt, Brick, Stone | Powerful and effective in dense materials. | Heavy and can be expensive to maintain. |

| Saw Cutter | Uses a toothed blade for cutting through hard surfaces. | Concrete, Asphalt | Versatile and effective for various applications. | May produce rough edges; noise pollution. |

| Laser Cutter | Employs high-intensity lasers for cutting. | Metal, Asphalt, Plastic | Exceptional precision with minimal heat-affected zone. | High energy consumption and equipment costs. |

Excellence in Asphalt Cutter Sets the Industry Standard Market Leader

L

Laura Wilson

I highly recommend this product. The quality is top-tier, and the after-sales support is unmatched.

17 June 2025

N

Natalie Green

Impressed with my purchase! The customer service team is professional and truly cares about their clients.

29 June 2025

E

Eric Campbell

This product is superior in quality, and the service was impressively responsive.

21 May 2025

A

Alicia Sanchez

Very happy with the product and the incredible level of customer service I received.

21 June 2025

T

Tommy Wood

Product quality is excellent! The after-sales team was knowledgeable and supportive.

13 May 2025

M

Mark Jameson

Outstanding item! The after-sales team delivered service that was both professional and efficient.

31 May 2025

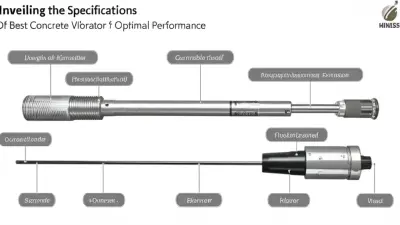

Internal Vibrator

Internal Vibrator  External Vibrator

External Vibrator  Submersible Pump

Submersible Pump  Eccentric shaft

Eccentric shaft  Pendulum shaft

Pendulum shaft  Portable vbrator shaft

Portable vbrator shaft  Portable concrete mixer

Portable concrete mixer  Vertical concrete mixer

Vertical concrete mixer  Hydraulic concrete mixer

Hydraulic concrete mixer  Walk behind power trowel

Walk behind power trowel  Ride on power trowel

Ride on power trowel  Concrete screed

Concrete screed  Floor Grinding machine

Floor Grinding machine  Concrete cutter

Concrete cutter  Scarifying machine

Scarifying machine  Tamping rammer

Tamping rammer  Plate compactor

Plate compactor  Vibratory roller

Vibratory roller