Top concrete vibrator manufacturer from Max Machine

Max Machine stands as the top concrete vibrator manufacturer, driven by advanced engineering and strict quality control. The company’s commitment to customer-focused solutions sets it apart in the industry. Innovative technology and a global reach ensure Max Machine delivers durability and efficiency on every project. Selecting a reputable manufacturer like Max Machine can transform construction outcomes. For example, projects using advanced vibrators have reported up to 30% faster compaction and 25% higher production efficiency, highlighting the value of expert equipment in achieving project success.

Key Takeaways

- Max Machine leads the concrete vibrator market with advanced technology and strict quality control.

- Concrete Vibrators improve concrete strength, reduce cracks, and speed up construction projects.

- Choosing the right vibrator type depends on project size, concrete mix, and application needs.

- Max Machine offers durable, customizable vibrators with fast global delivery and strong after-sales support.

- The company uses digital tools and IoT features to help monitor and optimize equipment performance.

- Max Machine’s products meet international safety and environmental standards, supporting sustainable construction.

- Their expert team provides personalized consultation to help clients select the best equipment.

- Clients benefit from a smooth ordering process, reliable warranty, and responsive technical assistance.

Understanding Concrete Vibrators

What Is a Concrete Vibrator?

Definition and Function

A concrete vibrator is a specialized tool used in construction to compact freshly poured concrete. This device removes trapped air and excess water, ensuring the mixture settles densely around reinforcement bars and within formwork. By vibrating the concrete, the tool helps eliminate air pockets, which can weaken the structure if left unaddressed. Contractors rely on concrete vibrators to achieve a smooth, durable finish and to meet strict engineering standards.

Types of Concrete Vibrators

The construction industry classifies concrete vibrators into several main types, each designed for specific tasks and environments. The table below summarizes these types, their descriptions, and typical applications:

| Type of Vibrator | Description | Key Characteristics / Applications |

|---|---|---|

| Internal Vibrators | Inserted directly into concrete to vibrate and compact it | Most common; used in beams, columns, and walls; requires systematic insertion and withdrawal |

| Surface Vibrators | Vibrate directly on the concrete surface | Ideal for slabs and thin layers; effective for large surface areas; smooths and levels concrete |

| External Vibrators | Mounted on formwork to transmit vibration through it | Suitable for small cross-sections like columns and beams; compacts concrete without disturbing reinforcement |

| Vibrating Tables | Table vibrates to compact concrete | Used mainly in precast plants and labs; frequency and amplitude adjustable for different consistencies |

Tip: Selecting the right type of vibrator depends on the project’s size, the concrete’s thickness, and the presence of reinforcement.

Importance in Construction

Ensuring Structural Integrity

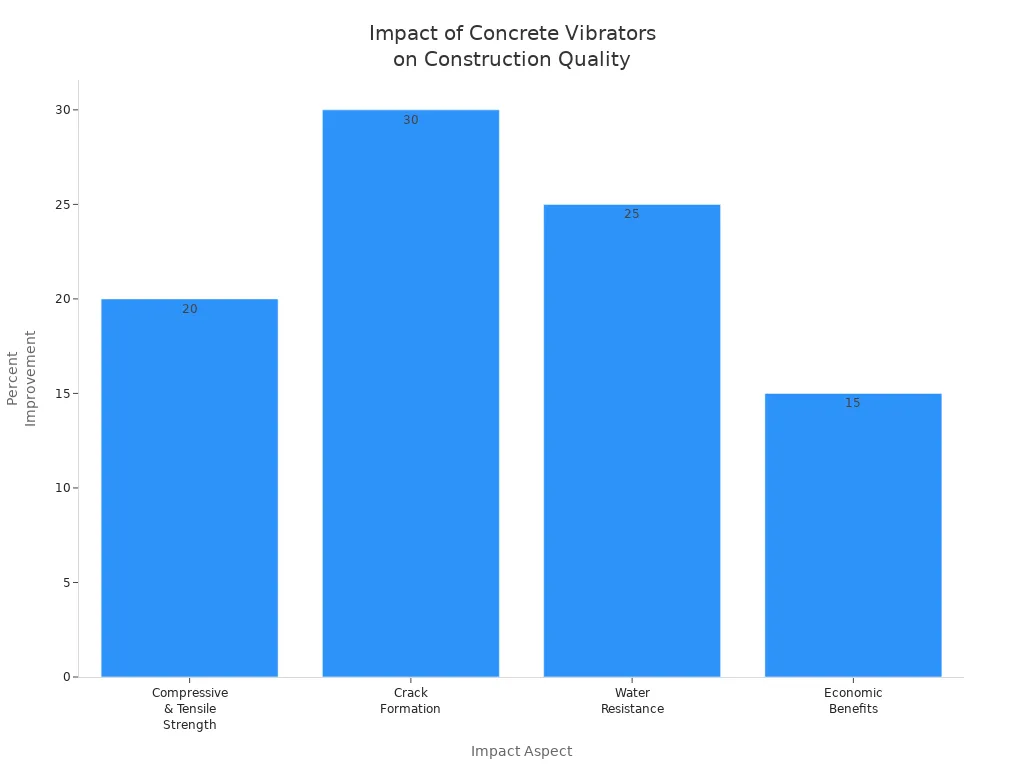

Concrete vibrators play a vital role in strengthening buildings and infrastructure. Proper vibration increases both compressive and tensile strength by up to 20%. It also reduces crack formation by as much as 30% and improves water resistance by 25%. By eliminating voids and air pockets, vibrators create denser, more durable concrete that resists moisture and freeze-thaw cycles. The chart below illustrates these improvements:

Dense, well-compacted concrete stands up better to weather, earthquakes, and daily wear, ensuring long-term safety and reliability.

Enhancing Work Efficiency

Concrete vibrators also boost efficiency on construction sites. Workers use them to speed up large pours, finish slabs and foundations, and reach difficult areas such as deep columns or tight corners. The following list highlights common applications:

- Compacting concrete in walls, columns, and foundations

- Finishing slabs for residential, commercial, and industrial projects

- Working in hard-to-reach or heavily reinforced areas

- Repairing and maintaining aging structures, including bridges and dams

- Filling voids under sidewalks and patching parking structures

By streamlining these tasks, concrete vibrators help crews complete projects faster and with fewer errors, reducing costs and minimizing delays.

top concrete vibrator manufacturer: Max Machine’s Leadership

Company Background and Growth

Established Expertise Since 1997

Max Machine began its journey in 1997. The company quickly earned a reputation for reliability and technical skill. Over the years, Max Machine built a strong foundation by combining industry wisdom with a forward-thinking approach. The team includes both veteran engineers and energetic young professionals. This blend of experience and innovation drives the company’s continued growth.

Vertically Integrated Manufacturing-Trade Model

Max Machine operates as a vertically integrated manufacturing-trade enterprise. The company manages every step, from design and production to global distribution. This model ensures strict quality control at each stage. Clients benefit from consistent product standards and fast delivery. The seamless integration of manufacturing and trading allows Max Machine to respond quickly to market changes and customer needs.

Technical Mastery and Innovation

Veteran Engineers and R&D Excellence

A team of seasoned engineers leads Max Machine’s research and development. These experts focus on improving durability, safety, and performance. They test new materials and refine designs to meet the demands of modern construction. The R&D team works closely with clients to understand real-world challenges. Their efforts result in products that perform reliably in tough environments.

Digital Solutions and Customization

Max Machine invests in digital technology to enhance its products. The company offers IoT-enabled vibration analytics, which help users monitor equipment performance in real time. Customization stands as a core strength. The team adapts solutions for projects of all sizes, from large infrastructure builds to smaller, specialized jobs. Clients receive tailored products that match their exact requirements.

Note: Max Machine’s digital tools and custom services help contractors optimize workflows and reduce downtime.

Product Range and Specialization

Concrete Vibrators and Motors

Max Machine, recognized as a top concrete vibrator manufacturer, offers a wide selection of concrete vibrators and motors. The MaxXT line includes electric and portable models. These tools remove air pockets and ensure proper concrete consolidation. The robust design suits both residential foundations and commercial structures. Contractors use these vibrators to prevent honeycombing and achieve smooth finishes. Max Machine supports dealers and professionals with wholesale options, free samples, and no minimum order quantity. Fast door-to-door shipping within seven days ensures timely project completion.

- Electric and Portable Concrete Vibrators for various construction needs

- Tools designed to prevent honeycombing and improve concrete quality

- Wholesale support with flexible order policies and rapid shipping

Auxiliary Construction Equipment

In addition to vibrators, Max Machine supplies auxiliary construction equipment. The product range covers tools that support concrete placement and finishing. Each item meets strict quality standards. The company’s focus on durability and efficiency helps builders complete projects on time and within budget.

Contractors and builders worldwide trust Max Machine for reliable equipment and responsive service. The company’s leadership as a top concrete vibrator manufacturer reflects its dedication to quality, innovation, and customer satisfaction.

Quality Control and Customization

Rigorous Quality Assurance

Max Machine enforces strict quality assurance at every stage of production. The company uses advanced inspection systems and standardized testing protocols. Each concrete vibrator undergoes multiple checks for performance, safety, and durability. Engineers monitor the assembly process to ensure every component meets precise specifications. The vertically integrated model allows Max Machine to control material sourcing, manufacturing, and final inspection. This approach reduces the risk of defects and guarantees consistent product quality. Clients receive equipment that performs reliably, even in demanding construction environments.

Quality assurance at Max Machine extends beyond the factory floor. The team tracks product performance in real-world conditions and collects feedback from global clients. This continuous improvement cycle helps the company maintain its reputation as a top concrete vibrator manufacturer.

Tailored Solutions for Clients

Max Machine recognizes that every construction project has unique requirements. The company offers tailored solutions to address specific client needs. The engineering team collaborates with customers to design custom features, adjust technical specifications, and optimize equipment for different applications. Max Machine’s commitment to customization extends to digital innovation. The Max.AI platform enables rapid development of autonomous AI agents that adapt to client workflows. This low-code/no-code system integrates enterprise-grade tools and proprietary data, allowing clients to deploy customized AI applications in their own environments.

Case studies highlight the impact of these tailored solutions. For example, a major airline improved customer sentiment by 40% using Max.AI’s sentiment analysis tools. Another airline increased revenue per customer by 50% and boosted engagement by 7% through real-time product variant generation. These results demonstrate Max Machine’s ability to deliver impactful, client-focused solutions that drive measurable improvements.

Global Service and Support

Fast International Delivery

Max Machine supports clients worldwide with a robust logistics network. The company’s global freight-calculator platform streamlines international shipping and ensures fast, reliable delivery. Key features include:

- Support for ocean container shipping, air cargo, and moving solutions from the USA to destinations around the world.

- Connections to major cargo airports and ports, enabling efficient handling of both full and partial container loads.

- Real-time shipment tracking and expert customer support for enhanced reliability.

- Coverage for a wide range of cargo types, including machinery, vehicles, and commercial goods.

- Competitive rates and a streamlined booking process for easy logistics coordination.

The global service network includes over 100 freight stations across Europe and Israel, 13 locations in the US and Mexico, and 7 stations in Asia. Max Machine partners with exclusive airlines to prioritize urgent shipments up to 300 kg. Sameday Air deliveries can reach destinations in as little as 40 minutes, depending on customs and handling. The service operates every day of the year, ensuring rapid and dependable delivery for clients in every region.

Dedicated After-Sales Assistance

Max Machine provides comprehensive after-sales support to maximize client satisfaction. The support team offers technical guidance, troubleshooting, and maintenance tips for all equipment. Clients can access assistance through multiple channels, including phone, email, and online chat. The company’s commitment to service extends to warranty management and spare parts supply. Fast response times and knowledgeable staff help clients resolve issues quickly, minimizing downtime on construction sites.

Max Machine’s global reach and responsive support make it a trusted partner for builders, contractors, and distributors. The company’s dedication to quality, customization, and service reinforces its position as a top concrete vibrator manufacturer.

Unique Features of the top concrete vibrator manufacturer

Advanced Technology and Performance

High Frequency and Efficiency

Max Machine integrates advanced technologies into its concrete vibrators to deliver superior performance. The machines operate at high frequencies, typically between 12,000 and 15,000 rpm. This high-speed operation ensures effective concrete compaction and accelerates project timelines. The use of wireless lithium batteries increases portability, allowing workers to move freely across job sites. Adjustable shaft lengths, ranging from 1 to 2 meters, provide flexibility for different construction scenarios. The electric engines and motors are engineered for durability, supporting long-term use in demanding environments. All products comply with CE certification standards, ensuring safety and quality. Max Machine also offers video technical support and a comprehensive one-year warranty, which boosts user confidence and enhances after-sales service.

Performance metrics further demonstrate the efficiency of these vibrators:

| Performance Metric | Value / Description |

|---|---|

| Stage recognition accuracy | 95.5% (hybrid neural network) |

| Vibrator state recognition accuracy | 100% (pulled-out), 99% (inserted in plain concrete), 97% (inserted in reinforced concrete) |

| Vibration acceleration | Sensitive parameter reflecting working state |

| Vibration energy | Calculated from acceleration, frequency, amplitude, and time; relates to concrete state transition |

| Vibration duration | Recorded for different stages and media to evaluate quality |

| Media distinction ability | Model classifies vibration medium with high stability and accuracy |

The vibration tracking system uses two sensor types for hardware simplicity and reliability. Real-time quality control prevents vibration issues, ensuring consistent results.

Durability and Safety Enhancements

Max Machine designs its vibrators for longevity and safety. The robust construction withstands harsh job site conditions. Corrosion-resistant metal probes and triple-layer coatings protect internal components. Compliance with international safety standards, including CE certification, ensures safe operation. The company’s commitment to quality and safety positions it as a top concrete vibrator manufacturer trusted by professionals worldwide.

Customization and Flexibility

OEM and ODM Services

Max Machine offers extensive OEM and ODM services. Clients can request custom logos, packaging, and graphics for bulk orders. The engineering team adjusts material composition, such as chemical-resistant polymers for hazardous environments. Multiple power output levels—Base, Advanced, and Pro—allow clients to select the right tool for their project scale. Drive modes include gasoline, diesel, and electric, providing flexibility for various job sites.

Solutions for Diverse Project Needs

The company addresses diverse project requirements with specialized features. Probe sensor types, including pressure and temperature monitoring, support unique applications. Coiled hoses improve maneuverability and storage. Internal drive mechanisms ensure consistent vibration output. Real-time sensor integration and technical enhancements help clients meet specific technical and environmental demands.

Max Machine’s customization options enable contractors to optimize equipment for any construction scenario.

Sustainability and Eco-Conscious Design

Energy-Smart Manufacturing

Max Machine uses advanced artificial neural network models to predict and reduce environmental impacts. These models accurately estimate carbon footprints and water usage based on material types and design complexity. Simpler, modular designs and renewable biomaterials, such as bamboo, significantly lower emissions and resource consumption. The company’s data-driven approach allows rapid evaluation of eco-friendly alternatives before physical prototyping.

Recyclable Components

A product-based environmental management system, aligned with ISO 14001 standards, guides Max Machine’s eco-design process. This system manages environmental impacts throughout the product lifecycle, from design to disposal. Tools like eco-roadmapping and lifecycle assessments ensure continual improvement in sustainability. The company consistently reduces its environmental footprint and complies with regulations such as the EU RoHS directive.

Sustainability is embedded in every stage of Max Machine’s product development, supporting a greener future for the construction industry.

Comparing the top concrete vibrator manufacturer to Other Brands

Product Quality and Reliability

Material Selection and Engineering Standards

Max Machine selects premium materials for every concrete vibrator. The company uses high-grade metals and advanced polymers to ensure strength and resistance to wear. Each component meets strict engineering standards. The design team follows international guidelines for safety and performance. Other brands may use standard materials, but Max Machine invests in superior options to extend product life. This focus on quality materials helps prevent breakdowns and supports consistent operation on demanding job sites.

Longevity and Maintenance

Durability sets Max Machine apart from many competitors. Their vibrators withstand harsh environments, frequent use, and exposure to moisture or chemicals. The robust construction reduces the need for frequent repairs. Maintenance tasks remain simple due to modular designs and accessible parts. Many users report fewer breakdowns and longer service intervals compared to other brands. This reliability means less downtime and lower long-term costs for contractors and builders.

Price and Value Proposition

Cost-Effectiveness

Max Machine positions its products in the premium segment. The initial investment may be higher than some alternatives, but the value becomes clear over time. Contractors benefit from reduced maintenance, fewer replacements, and improved efficiency. The machines deliver consistent results, which helps avoid costly rework. Many users find that the total cost of ownership is lower when factoring in durability and performance.

Return on Investment

Max Machine justifies its pricing through a range of value-added features:

- Superior engineering and craftsmanship ensure each unit meets high standards.

- Innovative technology, such as IoT-enabled analytics, boosts productivity and quality control.

- Unique selling points, like modular eco-conscious designs, support sustainability goals.

- Long-term cost savings arise from fewer repairs and extended equipment lifespan.

- The brand’s reputation for reliability strengthens project outcomes and client trust.

These features help contractors achieve better results and maximize their return on investment. Max Machine’s approach supports both profit margins and brand perception as a leader in quality.

Service and Support Comparison

Pre-Sales Consultation

Max Machine provides expert guidance before purchase. The sales team listens to project requirements and recommends suitable models. They offer technical advice and help clients compare options. This consultative approach ensures buyers select the right equipment for their needs. Many other brands offer basic sales support, but Max Machine’s team delivers personalized service.

After-Sales Support

After the sale, Max Machine continues to support its clients. The company offers technical assistance, troubleshooting, and spare parts supply. Clients can reach support staff through multiple channels, including phone and online chat. Fast response times and knowledgeable technicians help resolve issues quickly. This level of after-sales care builds long-term relationships and keeps projects running smoothly. Other brands may not match the same commitment to ongoing support.

How to Choose the Right Concrete Vibrator

Assessing Project Requirements

Project Size and Scope

Selecting the right concrete vibrator begins with a clear understanding of the project’s size and complexity. Contractors should evaluate the type of concrete pour, such as walls, floors, columns, or curbs. The dimensions of the structure—height and width—directly influence the choice of equipment. Larger pours may require high-frequency or heavy-duty vibrators, while smaller or more intricate forms benefit from compact, flexible models. Reviewing job specifications and the amount of reinforcing steel present helps determine the most suitable vibrator type.

Concrete Type and Application

The characteristics of the concrete mix play a crucial role in equipment selection. Low-slump concrete, which is stiffer, demands high-frequency vibrators to achieve proper consolidation. High-slump concrete, which flows more easily, works best with flexible shaft vibrators. Understanding the mix design and slump ensures the vibrator matches the application, optimizing both quality and efficiency. Contractors should also consider the presence of additives or special requirements, as these can affect vibration needs.

Tip: Always match the vibrator type to the specific application for best results.

Key Features to Consider

Power and Frequency Options

Power and frequency determine how effectively a vibrator consolidates concrete. High-frequency models excel in dense or heavily reinforced pours, while standard-frequency units suit general applications. Contractors should assess electrical availability and the distance to power sources on the jobsite. Some projects may benefit from gas-powered or battery-operated models, especially where mobility is essential. The right power and frequency combination ensures efficient operation and consistent results.

Portability and Ease of Use

Portability and ergonomic design impact daily productivity. Lightweight, compact vibrators allow workers to maneuver easily around the site, reducing fatigue and increasing speed. Features such as adjustable shaft lengths and comfortable grips enhance usability. Contractors should also consider shaft length and jobsite limitations when making a selection. Easy-to-use controls and quick setup further streamline operations, especially on fast-paced projects.

- Portable models suit small pours and tight spaces.

- Ergonomic handles and balanced weight distribution improve operator comfort.

- Quick-connect systems simplify assembly and maintenance.

Evaluating Manufacturer Credentials

Certifications and Compliance

Reliable manufacturers provide equipment that meets international safety and quality standards. Certifications such as CE mark and ISO compliance indicate rigorous testing and adherence to industry regulations. These credentials assure contractors that the equipment will perform safely and consistently under demanding conditions.

Customer Reviews and Testimonials

Customer feedback offers valuable insight into product performance and reliability. Users of Max Machine concrete vibrators report improved battery life, seamless integration into workflows, and extended device longevity. Professionals, students, and industry experts praise the ease of use and cost-effectiveness. Positive testimonials highlight the brand’s commitment to quality and support, reinforcing its reputation as a trusted partner in construction.

Contractors should review both certifications and user experiences to make informed purchasing decisions.

Making the Final Decision

Comparing Offers and Warranties

Selecting the right concrete vibrator involves more than just evaluating technical features. Buyers should compare offers from different manufacturers to ensure they receive the best value. Max Machine provides a transparent pricing structure, which helps clients understand exactly what they pay for. Many contractors appreciate the detailed quotations that outline each component and service included.

A side-by-side comparison table can clarify the differences between manufacturers:

| Feature | Max Machine | Typical Competitor |

|---|---|---|

| Warranty Length | 12 months standard | 6-12 months |

| Customization Options | Extensive (OEM/ODM) | Limited |

| After-Sales Support | 24/7 global hotline | Business hours only |

| Delivery Time | 7 days (door-to-door) | 2-4 weeks |

| Technical Support | Video, phone, chat | Phone/email |

Max Machine stands out with its comprehensive warranty and rapid delivery. The company’s after-sales support operates around the clock, which ensures clients receive help whenever they need it. Customization options also give buyers flexibility to match equipment to their project requirements.

Tip: Always review warranty terms carefully. A longer warranty period and responsive support can save time and money if issues arise.

Ordering from Max Machine

Placing an order with Max Machine follows a straightforward process. The company’s team guides clients from initial inquiry to final delivery. Buyers can request a quote online or contact the sales team directly. Max Machine responds quickly, often within 24 hours, to provide detailed product information and pricing.

The ordering process typically includes these steps:

- Inquiry Submission: Clients send project details and requirements through the website or by email.

- Consultation: The sales team reviews the information and recommends suitable models.

- Quotation: Max Machine provides a clear, itemized quote, including shipping options and estimated delivery times.

- Order Confirmation: Clients confirm the order and finalize payment.

- Production and Quality Check: The factory prepares the equipment, performing rigorous quality checks before shipment.

- Shipping and Tracking: Max Machine arranges fast, global delivery with real-time tracking updates.

- After-Sales Support: The support team remains available for technical assistance and warranty service.

Max Machine’s streamlined process reduces delays and ensures clients receive reliable equipment on schedule. The company’s commitment to transparency and support builds trust with contractors and project managers worldwide.

Ordering from Max Machine means more than just purchasing a tool. Clients gain a partner dedicated to their project’s success. The company’s expertise, fast logistics, and responsive service make it a top choice for concrete vibrators and construction equipment.

Success Stories with the top concrete vibrator manufacturer

Real-World Applications

Large-Scale Construction Projects

Max Machine equipment powers some of the world’s most ambitious construction projects. Major contractors rely on their concrete vibrators to build skyscrapers, bridges, and highways. For example, a leading infrastructure company in Southeast Asia used Max Machine vibrators during the construction of a 50-story commercial tower. The team reported faster compaction times and fewer structural defects. Project managers noted that the vibrators’ high frequency and robust design helped them meet strict deadlines. The equipment performed well in challenging weather and heavy-duty environments.

Another case involved a European civil engineering firm working on a high-speed rail project. The company selected Max Machine for its advanced vibration analytics and real-time monitoring. Engineers tracked compaction quality using IoT-enabled features. This approach reduced rework and improved overall concrete strength. The project finished ahead of schedule, saving both time and resources.

Small and Medium Enterprises

Small and medium enterprises (SMEs) also benefit from Max Machine solutions. A family-owned construction business in South America upgraded its equipment with Max Machine’s portable vibrators. The owner reported smoother slab finishes and fewer callbacks from clients. Workers found the machines easy to operate and maintain. The company completed more projects each month, increasing revenue and customer satisfaction.

A mid-sized contractor in Africa used Max Machine’s customizable vibrators for rural infrastructure projects. The team appreciated the flexible shaft lengths and energy-efficient motors. These features allowed them to work in remote locations with limited power supply. The contractor delivered reliable results on time, earning new contracts in the region.

Customer Testimonials

Product Performance Satisfaction

“Max Machine vibrators deliver consistent results every time. Our team trusts their durability and high-frequency performance on every job.”

— Site Manager, Global Construction Firm

A project supervisor in the Middle East shared, “We saw a 20% reduction in concrete defects after switching to Max Machine. The equipment is reliable and easy to use.”

Experiences with Max Machine Support

“The after-sales support from Max Machine is outstanding. Their team responds quickly and provides clear solutions.”

— Operations Director, Infrastructure Company

A small business owner added, “Ordering was simple, and delivery was fast. The support team helped us set up the equipment and answered all our questions.”

These stories highlight why many consider Max Machine the top concrete vibrator manufacturer for projects of all sizes.

Max Machine stands as the top concrete vibrator manufacturer, delivering expertise, innovation, and customer-focused solutions.

- Advanced technology and strict quality control drive consistent results.

- Responsive global support ensures every client receives timely assistance.

For more information or to request a quote, contact Max Machine today and experience the difference in your next construction project.

FAQ

What types of concrete vibrators does Max Machine offer?

Max Machine provides internal, surface, and external vibrators. The product line includes electric, portable, and customizable models. Each type suits different construction needs, from large infrastructure projects to small repairs.

How does Max Machine ensure product quality?

The company uses strict quality control at every production stage. Engineers test each unit for durability, safety, and performance. Max Machine follows international standards and holds CE certification.

Can Max Machine customize equipment for specific projects?

Yes. Max Machine offers OEM and ODM services. The engineering team adapts features, branding, and technical specifications to meet unique project requirements.

How fast can Max Machine deliver orders internationally?

Max Machine ships most orders within seven days. The global logistics network supports fast, reliable delivery to over 50 countries. Real-time tracking keeps clients informed.

What after-sales support does Max Machine provide?

Clients receive technical assistance, troubleshooting, and spare parts supply. The support team responds quickly through phone, email, or online chat. Warranty management ensures peace of mind.

Are Max Machine’s products eco-friendly?

Yes. The company uses recyclable materials and energy-smart manufacturing. Max Machine follows ISO 14001 standards and complies with EU RoHS directives for environmental responsibility.

How can clients place an order with Max Machine?

Clients submit project details online or by email. The sales team provides consultation, a detailed quote, and guides the order process. Fast response and transparent communication ensure a smooth experience.

What certifications do Max Machine products have?

All products meet CE certification requirements. The company also follows ISO quality and environmental management standards. These certifications guarantee safety and reliability.

Internal Vibrator

Internal Vibrator  External Vibrator

External Vibrator  Submersible Pump

Submersible Pump  Eccentric shaft

Eccentric shaft  Pendulum shaft

Pendulum shaft  Portable vbrator shaft

Portable vbrator shaft  Portable concrete mixer

Portable concrete mixer  Vertical concrete mixer

Vertical concrete mixer  Hydraulic concrete mixer

Hydraulic concrete mixer  Walk behind power trowel

Walk behind power trowel  Ride on power trowel

Ride on power trowel  Concrete screed

Concrete screed  Tamping rammer

Tamping rammer  Plate compactor

Plate compactor  Vibratory roller

Vibratory roller