What Size Concrete Cutter Fits Small Renovations vs. Large Projects?

Choosing the right Concrete Cutter is vital. It ensures your project succeeds, stays safe, and works efficiently. The tool's size matches your work's scale. Small renovations need tools that are easy to move and precise. Large projects demand power, deep cutting, and durability. MAXMACH offers a range of cutters for every task.

Key Takeaways

- Choose a concrete cutter that matches your project size. Small jobs need portable, precise tools. Large projects need powerful, efficient machines.

- Handheld cutters work best for small renovations. They offer control and fit tight spaces. Walk-behind saws are ideal for big projects. They make long, straight cuts.

- Always consider safety and dust control. Use water to cool blades and reduce dust. Never use gas cutters indoors due to harmful fumes.

Understanding Concrete Cutter Types

You need to know the different types of concrete cutters available. Each type serves specific purposes. Choosing the right one makes your job easier and safer.

Handheld Cutters for Versatility

Handheld cutters offer great versatility. You can easily maneuver them in tight spaces. They are perfect for smaller jobs or detailed work. These cutters come in electric or gas-powered models. You hold them directly, giving you control for precise cuts.

Tip: Handheld cutters are excellent for cutting openings for windows or doors in existing concrete.

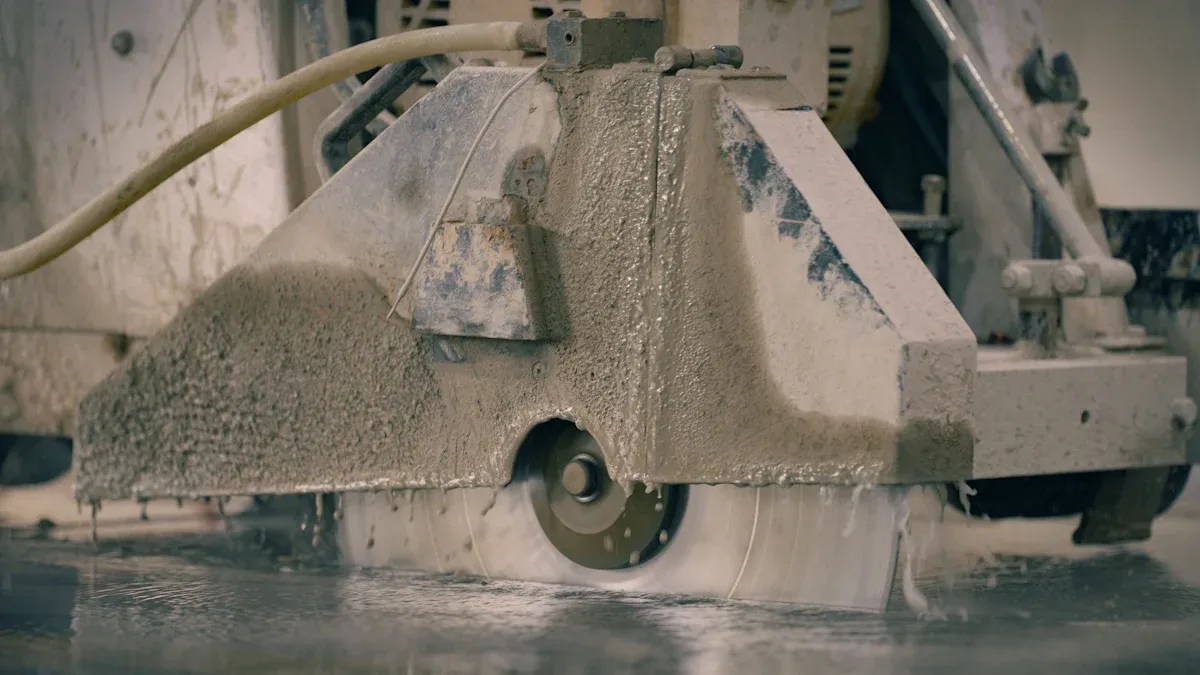

Walk-Behind Saws for Straight Cuts

Walk-behind saws are ideal for long, straight cuts. You push them across the concrete surface. These saws are much larger and more powerful than handheld models. They cut through roads, floors, and large slabs efficiently. You get consistent depth and straight lines with these machines.

Specialized Saws: Ring and Chain Options

Some jobs require specialized tools. Ring saws use a unique blade design. This design allows you to cut deeper than standard circular blades. Chain saws, on the other hand, use a diamond-studded chain. You use them to cut square openings or perfect corners without overcutting. These saws are great for precise, intricate cuts.

Hydraulic and Track Saws for Precision

Hydraulic and track saws provide extreme power and precision. Hydraulic saws use fluid pressure for immense cutting force. You often see them on heavy-duty construction sites. Track saws mount onto a guide rail. This rail ensures perfectly straight and accurate cuts every time. You use them for structural modifications where exactness is critical.

Concrete Cutters for Small Renovations

When you tackle small renovations, your tools need to match the job. You want equipment that helps you work smart, not just hard.

Ideal for Precision and Portability

Small renovation projects often involve tight spaces and detailed work. You need a concrete cutter that offers both precision and portability. Think about cutting a new doorway, removing old tiles, or creating channels for new wiring. These tasks demand a tool you can easily maneuver. You also need to make accurate cuts without damaging surrounding structures. A lightweight, compact cutter allows you to work comfortably for longer periods. It also helps you reach awkward spots.

Remember: Precision means you cut exactly where you intend. Portability means you can move the tool easily around your workspace.

Recommended Handheld MAXMACH Cutters

For small renovations, handheld concrete cutters are your best friend. MAXMACH offers several models perfect for these jobs. You might choose an electric handheld cutter for indoor work. These cutters produce no exhaust fumes, making them safer for enclosed spaces. They are also generally lighter. If you need a bit more power for tougher materials or outdoor tasks, a small gas-powered MAXMACH handheld cutter could be ideal. These tools give you excellent control. You can make intricate cuts for plumbing, electrical boxes, or decorative concrete work.

- Electric Handheld Cutters:

- Great for indoor use.

- Produce no emissions.

- Offer precise control.

- Small Gas Handheld Cutters:

- Provide more power.

- Suitable for outdoor tasks.

- Excellent for tougher materials.

Key Considerations for Small Projects

Before you pick your concrete cutter for a small renovation, think about a few important points.

- Required Cutting Depth and Material: How deep do you need to cut? Are you cutting concrete, brick, or tile? Different materials and depths require specific blade types and power levels.

- Power Source and Site Accessibility: Do you have access to electricity? If not, a gas-powered cutter is necessary. Consider if the work area is well-ventilated for gas fumes.

- Dust Control: Concrete cutting creates a lot of dust. For indoor projects, you must use wet cutting methods or a dust extraction system. This protects your health and keeps the work area cleaner.

- Noise Levels: Some cutters are very loud. If you work in a residential area, consider noise-reducing models or plan your work during appropriate hours.

- Operator Skill and Safety Protocols: Always wear proper safety gear. Make sure you feel comfortable and skilled enough to operate the chosen MAXMACH tool safely. If you are unsure, seek training or professional help.

Concrete Cutters for Large Projects

Power and Efficiency for Extensive Work

Large projects demand different tools. You need concrete cutters with immense power. They must work efficiently for extensive tasks. Think about cutting long stretches of highway. Consider removing large concrete slabs. You might need to cut deep trenches. These jobs require machines that handle continuous, heavy-duty work. They offer superior cutting depth and speed. This saves you time and labor costs. You get the job done faster.

Recommended Walk-Behind MAXMACH Saws

Walk-behind saws are your go-to for large projects. You push these powerful machines across the concrete. They make long, straight cuts with ease. MAXMACH offers a range of robust walk-behind saws. These saws feature strong engines, often gas or diesel. They use large diamond blades. These blades cut through thick concrete quickly. Many models include water systems. These systems cool the blade and control dust. Some MAXMACH saws are self-propelled. This reduces operator fatigue on big jobs. You can cut expansion joints in new roads. You can also cut large sections for demolition.

Key Considerations for Large-Scale Operations

When you plan large-scale concrete cutting, consider several factors.

- Cutting Depth and Material: You often need to cut very deep. You might cut through reinforced concrete. Choose a saw that handles these demands.

- Power Source and Fuel Capacity: Large saws use a lot of fuel. You need reliable access to gas or diesel. Ensure the machine has a large fuel tank for long operating hours.

- Dust and Slurry Management: Cutting large areas creates much dust and slurry. You must have effective dust suppression. You also need a plan for slurry disposal. This protects workers and the environment.

- Operator Comfort and Safety: Operators spend many hours on these machines. Look for features that reduce vibration. Good ergonomics help prevent fatigue. Safety guards are essential.

- Maintenance and Support: Large projects cannot afford downtime. You need a reliable machine. MAXMACH provides excellent support and parts availability. This keeps your project moving.

- Logistics: You must transport these heavy machines. Plan for their movement to and from the site. Consider water supply for wet cutting.

Factors Influencing Your Concrete Cutter Choice

You must consider several factors when choosing a concrete cutter. These points guide you to the best tool for your job.

Required Cutting Depth and Material

First, think about your cutting depth. How deep do you need to cut? Different saws offer various maximum depths. You also need to identify the material. Are you cutting concrete, asphalt, brick, or stone? Each material requires a specific blade type. A diamond blade works well for concrete.

Power Source and Site Accessibility

Consider your power source. Do you have electricity on site? Electric cutters are great for indoor use. They produce no fumes. Gas-powered cutters offer more mobility. You can use them in remote areas. Remember, gas saws need good ventilation.

Project Duration and Frequency of Use

Think about how long your project lasts. Will you use the cutter often? For short, infrequent tasks, a less expensive model might work. If you cut concrete daily, invest in a durable, heavy-duty machine. It will last longer.

Budget and Operating Costs

Your budget is important. The initial purchase price varies greatly. Also, consider operating costs. Fuel, blades, and maintenance add up. A cheaper saw might cost more in the long run.

Operator Skill and Safety Protocols

Finally, assess your skill level. Some cutters require more experience. Always prioritize safety. Wear proper protective gear. Understand the machine's operation before you start.

Matching MAXMACH Cutters to Project Scale

Choosing the right concrete cutter makes your project successful. You match the tool's capabilities to your job's demands. This ensures efficiency, safety, and the best results.

Small Renovation Checklist

Small renovations need tools that offer precision and easy handling. You often work in tight spaces. You need to make accurate cuts without causing extra damage. Consider these points when selecting a cutter for your smaller tasks:

- Cutting Depth: How deep do you need to cut? Most small renovations require shallow to medium depths. A handheld cutter usually provides enough depth for these jobs.

- Maneuverability: Can you easily move the cutter around obstacles? Handheld electric or small gas saws offer excellent control. You can cut curves or intricate shapes.

- Power Source: Do you have access to electricity? Electric cutters are perfect for indoor work. They produce no fumes. If you work outdoors or lack power, a gas-powered handheld cutter is a good choice.

- Dust Control: How will you manage dust? Small projects, especially indoors, need good dust control. Use wet cutting methods or a vacuum attachment. This keeps your workspace clean and safe.

- Noise Level: Will noise be an issue? Electric cutters are generally quieter than gas models. Consider your neighbors or other people in the building.

- Material Type: What material are you cutting? You might cut concrete, tile, or brick. Ensure your blade matches the material for efficient cutting.

- Operator Comfort: Can you comfortably hold and operate the tool for the required time? Look for ergonomic designs.

Tip: For small, precise cuts like creating openings for electrical boxes or plumbing, a compact, handheld MAXMACH cutter gives you the control you need.

Large Project Checklist

Large projects demand power, speed, and endurance. You often cut long distances or through very thick concrete. Your tools must handle continuous, heavy-duty work. Use this checklist to guide your choice for big jobs:

- Cutting Depth and Length: How deep and how long are your cuts? Large projects often require significant depth. You also need to cover long distances. Walk-behind saws excel at these tasks.

- Power and Speed: Do you need to cut quickly through tough materials? Look for powerful engines, often gas or diesel. These machines maintain high blade speed under load.

- Durability: Will the cutter withstand continuous use over many hours or days? Heavy-duty construction is essential. You need a machine built for the long haul.

- Dust and Slurry Management: How will you handle large amounts of dust and slurry? Large saws often have integrated water systems. These systems cool the blade and suppress dust. Plan for proper slurry collection and disposal.

- Operator Fatigue: Will the operator be working for extended periods? Self-propelled walk-behind saws reduce physical strain. Features like vibration dampening also help.

- Fuel Capacity: Can the machine run for long periods without refueling? Large fuel tanks minimize downtime.

- Site Logistics: How will you transport the cutter to and from the site? These machines are heavy. Plan for appropriate lifting and moving equipment.

- Blade Size and Type: What size and type of blade do you need for the material and depth? Large projects often use bigger diamond blades.

Note: For cutting long expansion joints in a new road or removing large concrete slabs, a robust walk-behind saw is indispensable. It provides the necessary power and stability.

Choosing the right concrete cutter ensures project success and safety. For small renovations, prioritize maneuverability and precision. Handheld electric or small gas saws are ideal. Large projects need powerful walk-behind or heavy-duty saws for depth and efficiency. Match the tool's capabilities to your project. This maximizes productivity and minimizes risks.

FAQ

What is the main difference between handheld and walk-behind concrete cutters?

Handheld cutters offer precision and portability for small jobs. Walk-behind saws provide power and efficiency for long, straight cuts on large projects.

Do I need water when cutting concrete?

Yes, you often need water. Water cools the blade. It also controls dust. This protects your health and extends blade life.

Can I use a gas-powered concrete cutter indoors?

No, you should not use gas cutters indoors. They produce harmful fumes. Always ensure good ventilation. Electric cutters are safer for indoor use.

Internal Vibrator

Internal Vibrator  External Vibrator

External Vibrator  Submersible Pump

Submersible Pump  Eccentric shaft

Eccentric shaft  Pendulum shaft

Pendulum shaft  Portable vbrator shaft

Portable vbrator shaft  Portable concrete mixer

Portable concrete mixer  Vertical concrete mixer

Vertical concrete mixer  Hydraulic concrete mixer

Hydraulic concrete mixer  Walk behind power trowel

Walk behind power trowel  Ride on power trowel

Ride on power trowel  Concrete screed

Concrete screed  Tamping rammer

Tamping rammer  Plate compactor

Plate compactor  Vibratory roller

Vibratory roller