Why Choosing the Right Disc Size Boosts Concrete Grinder Efficiency

Choosing the right disc size for your Concrete Grinder optimizes material removal. It reduces operational time. You also improve finish quality. This significantly boosts efficiency. Disc size influences contact area. It affects pressure distribution. It also impacts motor strain. These factors are key to your MAXMACH grinder's performance and project success.

Key Takeaways

- Choose the right disc size for your concrete grinder. This makes your work faster and improves the finish.

- Large discs cover big areas quickly. Small discs work best for tight spots and detailed edges.

- Matching the disc size to your grinder's power helps your tool last longer. It also prevents motor strain.

How Disc Size Impacts Grinding Performance and Efficiency

Contact Area and Material Removal Rate

The size of your grinding disc directly affects the contact area. This is the amount of disc surface touching the concrete at any given moment. A larger disc covers more surface area. This means you remove more material with each pass. You complete large jobs faster. Think of it like painting a wall. A wider roller covers more space than a narrow brush. This speeds up your work. However, a very large disc can be harder to maneuver. You might find it less effective for tight spaces or detailed work.

Pressure Distribution and Abrasive Effectiveness

Disc size also changes how pressure distributes across the concrete surface. A smaller disc concentrates the grinder's weight and power into a smaller area. This creates higher pressure per square inch. This concentrated pressure makes the abrasive grit more effective. It helps you cut through tough coatings or remove stubborn imperfections. For example, you use a small disc to aggressively remove thick epoxy. A larger disc spreads the pressure over a wider area. This results in lower pressure per square inch. You achieve a smoother, more even finish. This is ideal for polishing or light surface preparation. You get a consistent look across the entire floor.

Motor Strain and Grinder Longevity

Your grinder's motor works hard to spin the disc. The size of the disc directly impacts this effort. A larger disc requires more power to rotate. It creates more friction against the concrete. This increases the strain on your grinder's motor. Over time, this extra strain can lead to overheating. It can also reduce the motor's lifespan. You want to avoid premature wear on your equipment. A smaller disc puts less demand on the motor. It requires less power to operate. This helps your MAXMACH grinder run cooler. It extends the life of your valuable tool. Always match the disc size to your grinder's power capabilities. This ensures optimal performance and durability.

Matching MAXMACH Disc Size to Specific Concrete Grinding Tasks

Large Discs for Broad Area Preparation and Aggressive Removal

You tackle vast concrete surfaces. You need a large disc. These discs excel at broad area preparation. They remove material aggressively. Imagine a warehouse floor. You want to strip old epoxy. A large MAXMACH disc covers more ground. It speeds up your work significantly. You achieve a high material removal rate. This saves you time on big projects. Large discs are perfect for leveling uneven slabs. They also remove thick coatings or glues. You use them for initial grinding passes. This prepares the surface for finer work. Remember, a powerful grinder pairs best with a large disc. This ensures optimal performance.

Tip: Always match your large disc with a grinder that has sufficient power. This prevents motor strain and ensures efficient grinding.

Medium Discs for Versatile General Grinding

You need a versatile tool. Medium discs offer excellent balance. They handle general grinding tasks well. You use them for many common projects. Think of a garage floor. You want to prepare it for a new coating. A medium MAXMACH disc provides good speed. It also gives you enough control. You can remove light coatings. You can smooth out minor imperfections. These discs work well for residential and commercial spaces. They are a go-to choice for most contractors. You get efficient material removal. You maintain good maneuverability. This makes them a practical option for everyday use.

- Versatile for most projects.

- Balances speed and control.

- Ideal for general surface preparation.

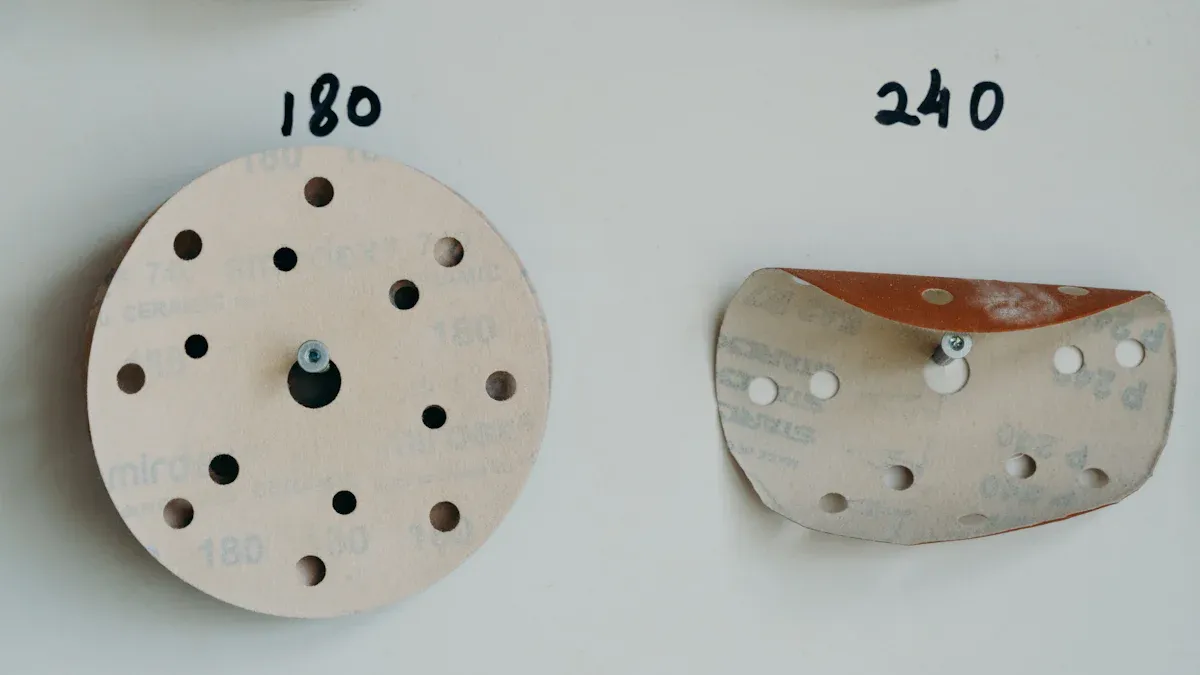

Small Discs for Precision and Edge Work

You face tight spots. You need precision. Small discs are your best friend. They excel at edge work. You reach corners easily. You grind around columns. Small MAXMACH discs fit into confined areas. They apply concentrated pressure. This helps you remove stubborn spots. You can tackle stair treads. You achieve a clean finish along walls. These discs are crucial for detailed work. They ensure no area gets missed. You get precise material removal. This guarantees a professional look for your entire project.

Small discs are indispensable for achieving a flawless finish in hard-to-reach areas. They define the quality of your detailed work.

Beyond Disc Size: Other Factors for Optimal Grinding Efficiency

Abrasive Grit and Bond Hardness

You choose more than just disc size. Abrasive grit and bond hardness also impact your grinding efficiency. Grit refers to the size of the cutting particles on your disc. Coarser grit removes material aggressively. You use it for heavy stock removal or stripping thick coatings. Finer grit creates a smoother finish. You choose it for polishing or preparing surfaces for thin coatings.

Bond hardness holds the abrasive particles. A soft bond releases worn grit quickly. This exposes new, sharp particles. You use a soft bond on hard concrete. A hard bond holds the grit longer. You use a hard bond on softer concrete. This prevents the disc from wearing out too fast. Matching grit and bond to your concrete type ensures maximum cutting power.

Grinder Power and RPM Compatibility

Your grinder's power and RPM (Revolutions Per Minute) are vital. You need enough power to spin your chosen disc effectively. A powerful grinder handles larger discs and tougher jobs without strain. If your grinder lacks power, it struggles. This reduces efficiency and can damage your equipment.

RPM also affects your grinding. Higher RPM means faster material removal. But it can generate more heat. This might damage heat-sensitive coatings or the concrete itself. Lower RPM gives you more control. You use it for delicate work or when you need a very smooth finish. Always match your disc to your grinder's power and RPM capabilities. This ensures optimal performance and extends the life of your MAXMACH equipment.

- High RPM: Faster removal, more heat.

- Low RPM: More control, less heat.

You maximize concrete grinder efficiency by selecting the correct disc size. This leads to faster project completion. You also get superior finish quality. Understand the interplay between disc size, task requirements, and grinder capabilities. This extends equipment lifespan. It enhances overall grinding operations.

FAQ

How does using a large disc affect my grinder?

You strain your grinder's motor. This causes overheating. It also shortens the motor's lifespan. Match disc size to your grinder's power. ⚠️

Which disc size should I choose for my project?

Consider your task. Use large discs for big areas. Choose medium discs for general work. Select small discs for precision and edges.

Can I use a small disc for a large concrete floor?

You can, but it takes much longer. Small discs are for precision. They are not efficient for broad material removal. Use the right tool for the job. 👍

Internal Vibrator

Internal Vibrator  External Vibrator

External Vibrator  Submersible Pump

Submersible Pump  Eccentric shaft

Eccentric shaft  Pendulum shaft

Pendulum shaft  Portable vbrator shaft

Portable vbrator shaft  Portable concrete mixer

Portable concrete mixer  Vertical concrete mixer

Vertical concrete mixer  Hydraulic concrete mixer

Hydraulic concrete mixer  Walk behind power trowel

Walk behind power trowel  Ride on power trowel

Ride on power trowel  Concrete screed

Concrete screed  Tamping rammer

Tamping rammer  Plate compactor

Plate compactor  Vibratory roller

Vibratory roller